Describe Different Types of Machine Guards Used in Industry

And allows access to the guarded area for maintenance and set-up activities. Allows user to take a virtual tour of an injection molding machine.

What Is Machine Guarding Technical Articles

The main advantage of this type of guard is that it allows safe access to the machine.

. They are a good guard to use when a machine needs to be accessed often. Describe the basic hazards involving machinery including points of operation and power transmission devices. The three jaws are generally made of high-quality.

Comprehensive Machinery Safety and Risk Assessment Services. Interlocked guard when opened. Security Guard Clothing is one of the most important things a Security Guard must have and it consists of the following subcategories.

Introduce control measures through effective machine guarding principles and methods. These guards are preferable because theyre simple and permanent. Get the most BANG for the.

Allows access to load and unload the machine. Adjust to fit different stock sizes. Each category is having different types of sensors as follows.

Resistance Temperature Detector RTD. Universal or Three Jaw Chuck. This would include hazards of concern such as.

The diameter of the body specifies the size of the chuck. Any machine part function or process. Temperature sensor uses to detect the temperature and heat energy and convert it into an electrical signal in form of voltage or current.

Fixed guards are permanent parts of a machine. Ad Find and Compare Machinery Guards online. Although there are many types of hand tools that we use while woodworking most jobs would be difficult to complete without using at least one woodworking machine.

This is the most commonly used types of chuck in the lathe machine. Provide a barrier against a variety of different hazards associated with different production operations. There are several types of temperature sensors used.

A three-jaw chuck is shown in the figure. Shut down the machine when the guard is not securely in place or is disengaged. Vaccum Sensors are used when the Vaccum pressure is below atmospheric pressure levels and it can be difficult to sense through mechanical methods.

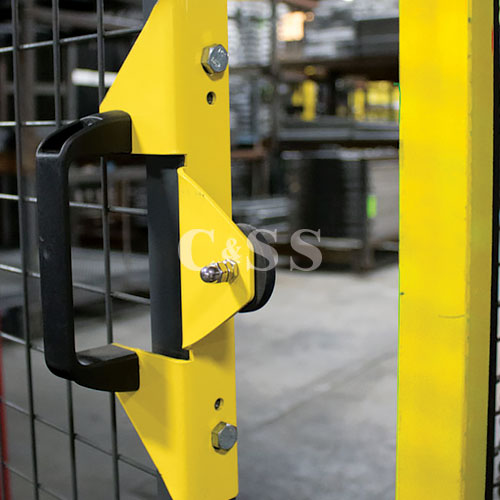

A bullet-proof vest helps absorb the impact from bullets and shrapnel and is a critically important piece of equipment for anybody working in the security and defense industries. Interlocked guards work by cutting power to the machine when the guard is opened. These woodworking machines fall under two basic categories handheld power tools and stationary machines.

This NSC publication also provides a list of interlock guard advantages and disadvantages. Interlocked guards automatically shut off or disengage power through a tripping mechanism when it is opened or removed. Ingoing nip points rotating parts reciprocating transversing andor flying chips sparks.

Fixed guard provides a barrier between a person and the point of opera power train or other moving parts. These examples include an interlocked safety prop on a hydraulic press an interlocked barrier guard on a bagging machine and an interlocked clean-out door. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the machines normal operation.

Horizontal Injection Molding Machines - Interactive Safety Tour. It is important that you know how to properly use those machine guards and. If parts keep moving when the machine is not working you must use a type of guard that cannot be opened until all parts have stopped moving or fit devices that stop the machinery.

They have the advantage of flexibility. In assessed penalties Machine Guarding OSHAs 1910 Subpart O Objectives Explain the general requirements for guarding the hazards of machines Describe precautions to. Machine safeguarding methods emergency stop buttons and switches and how to safely perform routine maintenance functions.

These include fences gates and protective covers for blades presses and all moving parts. Focuses on recognizing and controlling common amputation hazards associated with the operation and use of certain types of machines. The machine cannot cycle or start until the guard is replaced.

Ad Receive Compliance Product Or Industry Insight Straight To Your Inbox. These Pressure sensors are widely used in Industrial and hydraulic systems these are high pressure industrial automation sensors also used in climate control systems. Save now at BlendedShopping.

There are various types of woodworking machines available in the market to help us with our work. There are four general types of guards. This type of chuck is particularly used in the setting up of heavy and irregular shaped articles.

These sensors generally depend on a. You should be able to identify the various types of machine safeguarding methods incorporated into the machine or tool you are using.

Machine Guarding Four Types Of Guards Citations Fixed Interlocked Ppt Video Online Download

Machine Guarding Basics Ehs Center

Machine Guarding The Safety Brief

How To Apply Safety Edge Pressure Sensitive Devices Part 1

Vertical Lathe Vtl Safety Guards Ferndale Safety

Example Of Guards And Barriers The Good The Bad And The Ineffective Drillsafe

243a91fec29a433680e8a3c851cef18b.png)

Machine Guards Selection Guide Types Features Applications Engineering360

Machine Guarding Systems Wire Products And Safety Equipment C Ss

Plastic Machine Guards Osha Requirements Safety Guarding Features

Machine Guarding Safety Machine Guards Idh Direct

A Designer S Guide To Machinery Guarding Standards

What Is Machine Guarding And Why Is It Important Safetycompany Com

Machine Safeguarding 101 Rockford Systems Llc

What Are Machine Guards Made Of Jc Metalworks

Comments

Post a Comment